Electursys- Industrial IoT & AI based Predictive Maintenance Solution

Client

Karsten Moholt

Platforms

Web

An R&D project funded by Eureka and Innovate UK. Developed in collaboration with Karsten Moholt. Karsten Moholt is a specialist operator and maintenance provider for Offshore infrastructures like Oil & Gas rigs, wind turbines and more

Challenge

- Collect data points & build models to predict electrical component failures on Wind Turbines, so that the system can automatically schedule preventive maintenance.

- Providing reliable and consistent connectivity in various environments, including remote or harsh conditions.

- Handling the vast amounts of data generated by IoT devices requires efficient storage, processing, and analysis capabilities to derive actionable insights.

- Ensuring seamless integration and communication between diverse devices and platforms with different standards and protocols is a significant challenge.

- Protecting sensitive data and ensuring privacy are major concerns due to the increased number of connected devices, which can be vulnerable to cyber-attacks.

- Managing the growth of IoT networks, which may involve thousands or millions of devices, requires scalable solutions for data processing, storage, and communication.

Key Objectives

- To create a web-based solution that can be integrated with wind turbines to pull relevant data for predicting electrical failures,

- Execute technical R&D to understand data patterns that can help predict electrical component failures.

Solution

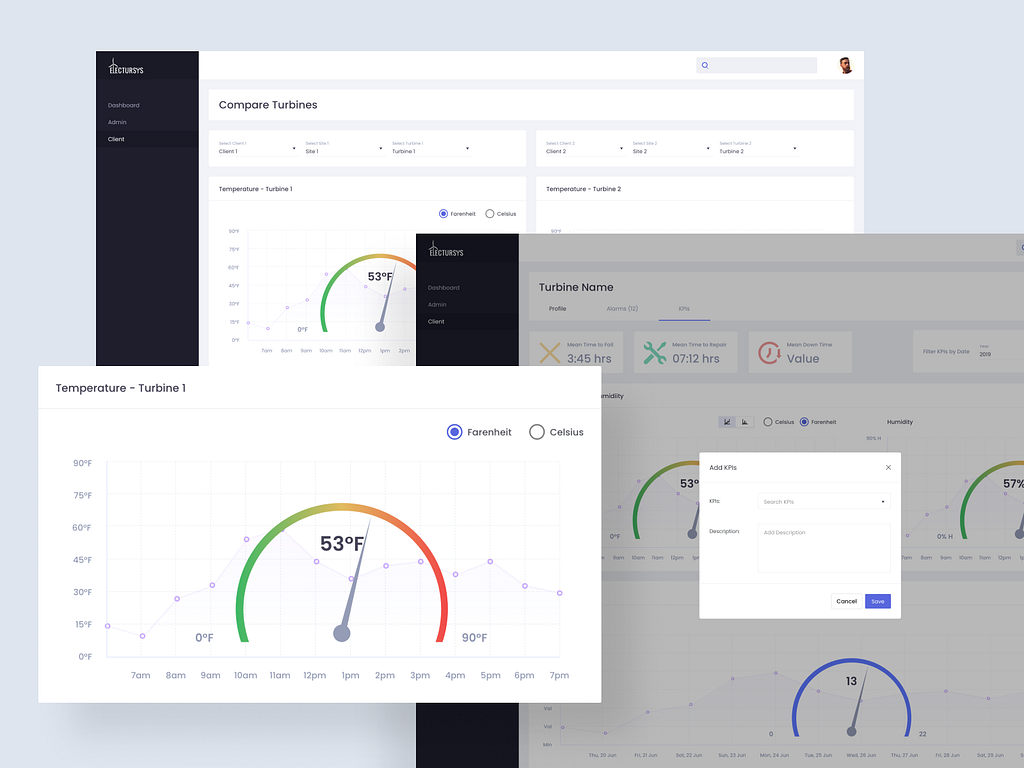

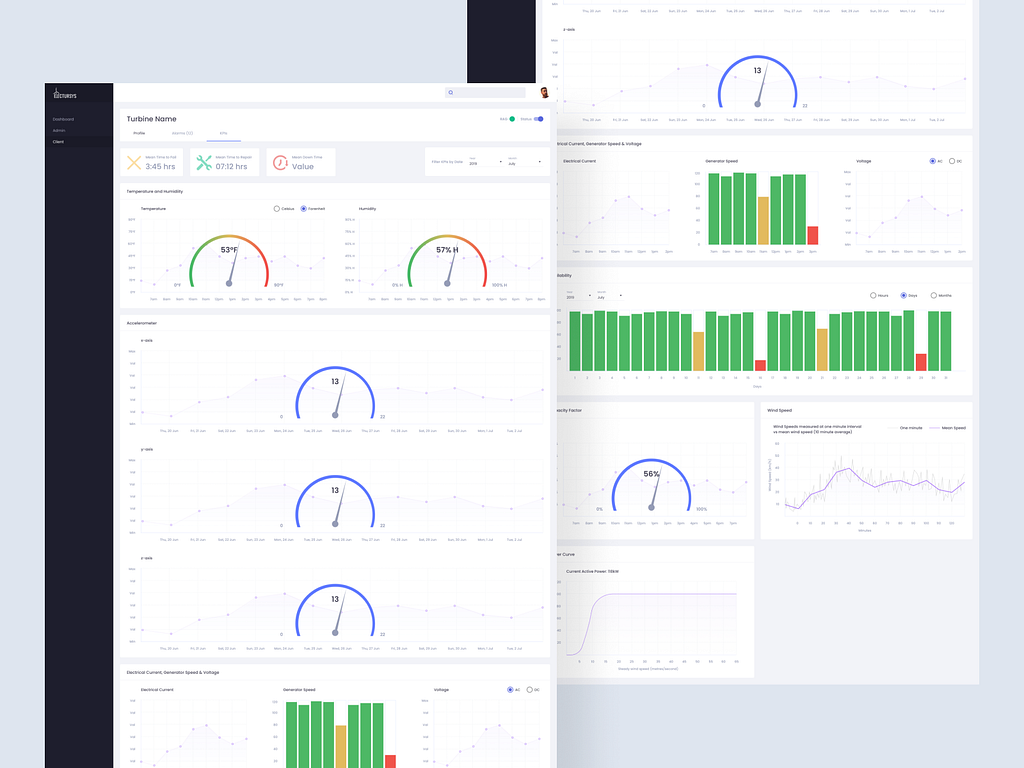

We created a comprehensive data model capable of predicting failures. In a wind turbine with over 10,000 components, our data model predicts both mechanical and electrical failures. It specifically forecasts when electrical failures may occur.

We developed a network architecture to collect various sensor data, created APIs for real-time data collection, implemented pre-processing to minimize latency, developed AI algorithms to predict faults, designed a UI to visualize data trends, and created a scheduling system for maintenance.

Technology used

Results