AI/ML

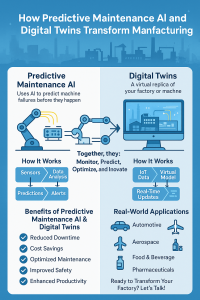

How Predictive Maintenance AI and Digital Twins Are Transforming Manufacturing

Predictive maintenance AI and digital twins in manufacturing.

Imagine a factory where machines warn you about potential breakdowns before they happen, and you can test new production ideas without touching a single piece of equipment. Sounds like something out of a sci-fi movie, right? Well, thanks to Predictive Maintenance AI and Digital Twin technology, this is the reality for modern manufacturers. These tools are changing the game, helping factories run smoother, save money, and stay one step ahead of problems. Let’s dive into how they work, why they matter, and what they mean for the future of manufacturing.

What is Predictive Maintenance AI?

Picture this: you’re running a busy factory, and one of your key machines suddenly breaks down. Production halts, deadlines slip, and repair costs pile up. Predictive Maintenance AI is like having a crystal ball for your equipment. It uses smart algorithms to analyze data from sensors on your machines – things like temperature, vibration, or even noise – to spot trouble before it turns into a full-blown failure.

How It Works

Here’s the gist of how predictive maintenance AI does its magic:

- Sensors Keep Watch: Tiny sensors on machines collect data non-stop, tracking things like how fast a motor’s spinning or if a pump’s overheating.

- AI Crunches the Numbers: The AI sifts through all this data, looking for patterns or weird blips that might signal a problem.

- Predicting the Future: Using what it’s learned from past data and real-time inputs, the AI predicts when a machine might fail – like saying, “Hey, that conveyor belt’s going to jam in two weeks.”

- Smart Alerts: The system pings the maintenance team with a heads-up, suggesting fixes or scheduling repairs when the factory’s quiet.

- Learning as It Goes: The more data the AI gets, the smarter it becomes, making its predictions sharper over time.

Why It’s a Game-Changer

- Less Downtime: No more surprise breakdowns that grind production to a halt. Predictive maintenance can cut unplanned downtime by up to 30%, keeping things running smoothly.

- Saving Cash: Fixing a small issue before it becomes a big one is way cheaper, and it helps machines last longer.

- Smarter Scheduling: Maintenance can happen during off-hours, so you’re not pausing production at the worst possible time.

- Safer Workplaces: Spotting problems early reduces the chance of accidents caused by faulty equipment.

- More Output: Reliable machines mean you can keep churning out products without hiccups.

Real-Life Examples

Predictive maintenance is already making waves in manufacturing:

- Car Makers: In automotive plants, AI monitors assembly-line robots. For example, it can predict when a robotic arm’s motor might fail, letting technicians fix it before it stops the line. This has slashed downtime and saved millions.

- Aerospace: Aircraft manufacturers use AI to keep tabs on engines and other critical parts “better safe than sorry” is the motto here.

- Food Production: In food and beverage factories, AI ensures equipment like mixers or conveyors stays in top shape, avoiding delays and keeping products safe.

- Pharma: In drug manufacturing, where precision is everything, predictive maintenance keeps machines compliant with strict regulations, avoiding costly mistakes.

What Are Digital Twins?

Now, let’s talk about Digital Twins – a technology that’s like having a virtual clone of your factory, machine, or even your entire supply chain. A digital twin is a real-time, virtual model that mirrors what’s happening in the physical world. It’s built using data from sensors, AI, and other tech to let you monitor, test, and tweak operations without touching the real thing.

How Digital Twins Come to Life

Here’s how a digital twin gets up and running:

- Data Flow: Sensors and devices like programmable logic controllers (PLCs) feed real-time data about machines, processes, or environments.

- Building the Twin: AI and algorithms create a virtual version of the physical asset – whether it’s a single machine or a whole factory.

- Staying in Sync: The twin updates constantly with fresh data, so it’s always an accurate reflection of what’s happening.

- Testing and Tweaking: You can run “what-if” scenarios – like, “What happens if we speed up this production line?” – to see outcomes without risking real-world disruptions.

- Actionable Tips: The twin offers insights, like how to cut energy use or avoid a bottleneck.

Why Digital Twins Are Awesome

- Real-Time Insights: You get a bird’s-eye view of your operations, spotting issues as they pop up.

- Better Processes: Simulate changes to find inefficiencies, like a slow-moving production step, and fix them virtually first.

- Lower Risks: Test new ideas in the digital world before rolling them out, avoiding costly real-world flops.

- Faster Innovation: Digital twins let you experiment with product designs or factory layouts, speeding up development.

- Greener Operations: Optimize energy use and cut waste, helping you hit sustainability goals.

Where Digital Twins Shine

- Factory Floors: A digital twin of a production line can show you where things are slowing down or if adding a new machine makes sense.

- Supply Chains: Model your supply chain to predict delays or optimize inventory, keeping things flowing smoothly.

- Product Design: Test how a product will perform in different conditions, catching flaws before production starts.

- Energy Savings: See where your factory’s using too much power and make tweaks to save money and the planet.

The Power of Combining Predictive Maintenance AI and Digital Twins

When you pair Predictive Maintenance AI with Digital Twins, it’s like having a super-smart assistant who not only warns you about problems but also shows you how they’ll affect your entire operation. Here’s how they team up:

- Spot and Solve: Predictive AI flags a potential machine issue, while the digital twin shows how that failure could ripple through your production line.

- Plan Smarter: Use the twin to simulate maintenance schedules, ensuring repairs happen at the least disruptive time.

- Save More: Together, they cut downtime, extend machine life, and optimize resources, saving you serious money.

- Innovate Faster: Insights from both tools can inspire new ways to design products or run your factory.

For instance, imagine a factory where predictive AI notices a motor’s starting to act up. The digital twin then models what happens if that motor fails – maybe it delays a key product line. With this info, you can prioritize fixing the motor during a quiet shift, keeping everything on track.

What’s Next for Manufacturing?

The future of manufacturing is all about working smarter, not harder. Predictive Maintenance AI and Digital Twins aren’t just about fixing machines – they’re about unlocking new ways to boost efficiency, spark innovation, and even go greener. As more factories embrace these technologies, we’ll see:

- Smarter Factories: AI and digital twins will make factories more adaptive, responding to changes in demand or supply in real time.

- Better Products: Virtual testing will lead to higher-quality, more reliable products.

- Sustainable Operations: Optimized processes will cut waste and energy use, helping manufacturers meet eco-friendly goals.

Ready to Transform Your Manufacturing?

If you’re excited about what Predictive Maintenance AI and Digital Twins can do for your factory, you’re not alone. These technologies are helping manufacturers big and small stay competitive in a fast-changing world. Whether you’re curious about monitoring a single machine or modeling an entire production line, there’s a solution out there for you.

Want to explore how these tools can work for your business? Let’s chat about your goals and how custom AI and software solutions can make them a reality. Reach out today, and let’s build the future of manufacturing together.